Apple

Pin

System

Construction

Method

Apple Pin

System

features

01

Design

Beauty of the wooden framework

In Apple Pin System (APS construction method), built-in metal fittings are used so they are not visible on the surface. Additionally, it corresponds to Kiln Dry Wood which is difficult to be used in hardware construction method, so beautiful finish such as expression of grain pattern unique to traditional Japanese wooden architecture can be achieved. Furthermore, stronger structure allows atrium or large space, respondimg flexibly to various lifestyles and family structures.

Structural calculation

Apple Pin System (APS construction method) also responds to needs of the times. Results of performance verification tests conducted by public institution demonstrated the durability of APS construction method; the results clarify strength of the building by structural calculation including wall quantity/N value calculation method and allowable stress calculation.

Apple Pin

System

features

02

Seismic resistance

Measures against thinned wood

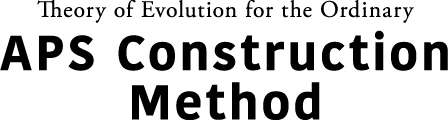

A study result shows that more than 10% of strength deterioration occurs when bolts are loosened due to earthquakes or thinned wood. Even laminated wood gets lean by 1 – 2 mm within several years. Originally, bolted joint has been invented from the concept of steel construction and therefore it is not suitable for wooden construction. Nonetheless, Apple Pin System (APS construction method) prevents loosening caused by repeated vibrations or earthquakes by its locking feature.

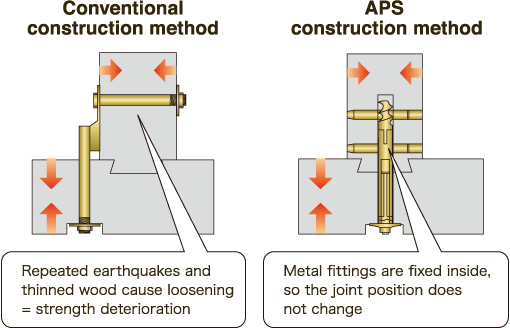

Reducing cross-section defect

Joint in wooden structure has an important role to transmit power from wood to wood, and it is the core that determines strength of the building and mitigates deformation. However, in conventional method, notches are required to joint wood. It causes cross-section defects that reduce strength of the wood. In Apple Pin System (APS construction method), cross-section defects are drastically reduced compared to conventional method, so the strength of the wood is maintained, bringing out the best of it.

Endurance test

In Apple Pin System (APS construction method), durability is improved by fitting the apple pins inside pillars/beams. As for safety aspect, endurance tests have been carried out at Government designated confirmation and inspection body designated and it has been proven that the product is highly seismic resistant and durable. Additionally, structural calculation makes it possible to clarify the strength of the building.

Apple Pin

System

features

03

Durability

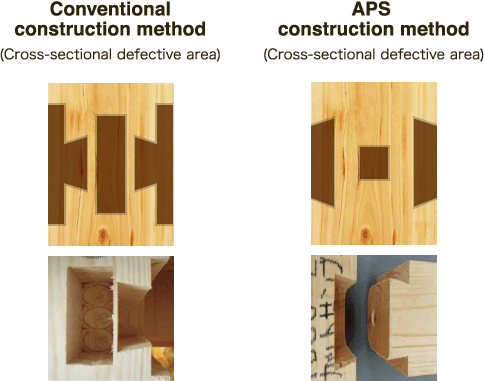

Fire prevention

In case of fire, Apple Pin System (APS construction method) has little impact of heat since metal fittings are fit at the center of the wood. The char layer formed on the surface when the wood is burnt limits oxygen supply inside the wood and works as an insulating layer, thereby slowing fire spread. The wood protects the metal fittings from the heat of fire and prevents deterioration of strength, so collapsing can be delayed to secure evacuation time and reduce danger associated with fire-fighting activity.

Airtightness

Apple Pin System (APS construction method) is a method which has less impact of thermal bridge compared to conventional method. Since metal fittings easily transfer heat, exposed metal fittings may cause condensation due to thermal bridge in conventional method or hardware method. Condensation may cause problems such as wood decay by generating rust or mold on metal fittings. Apple Pin System (APS construction method) makes metal fittings less exposed and eliminates impact of heat bridge and perforated slit to suppress air flow between floors, preventing reduction of airtightness and thermal insulation.

Apple Pin

System

features

04

Ecological

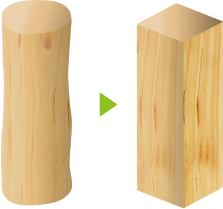

Domestic solid wood

In Japan, cedar or Japanese cypress which has excellent thermal insulation performance, beautiful grain pattern and humidity adjustment performance has been used for wooden architecture for a long time. However, as a result of liberalization of timber import which begun in 1955, timber self-sufficient rate has dropped to 50% or less in just 10 years, and the rate is 25% today. Apple Pin System (APS construction method) corresponds to domestic solid wood which is difficult to be used in conventional hardware construction method. It adds utility value for domestic wood materials that are suitable for Japanese climate and natural features, promotes reforestation in circulatory system and contribute to reduction in CO2 emissions.

Wood that has texture original to

natural wood cut out from raw timber

Reduced transport cost

In hardware construction method, metal fittings are normally fitted to the structural materials at a factory before bringing them into the site. Thus, the load becomes bulky compared to the conventional construction method and the transport cost is therefore increased. In Apple Pin System (APS construction method), volume of structural materials can be same as that in conventional method even after metal fittings have been fitted, so the transport cost can be reduced.

Reducing CO2 emissions

In Apple Pin System (APS construction method), metal fittings are miniaturized for the purpose of resource saving, so efficient transport is realized. It leads to reduction in CO2 emissions during transport. Furthermore, active use of wood, recycle of the materials and creation of environment for next-generation architecture are promoted.

Apple Pin

System

features

05

Quality control

Worldwide patents

Apple Pin System (APS construction method) has been adopted in the subsidized projects led by the Ministry of Land, Infrastructure, Transport and Tourism 3 years in a row. In addition, since it has been adopted in the category of technological development that contributes to improvement of safety in housings, its advanced technology is acknowledged, acquiring patents around the world.

- Japan

Patent number : No.4999618 - European Union

Patent number : No.2228550 - People’s Republic of China

Patent number : ZL2009 1 0128731.3

Precut Factory

Superior performance of Apple Pin System (APS construction method) is achieved through high processing accuracy and quality control. Structural materials are processed in millimeters at APS certified precut factories nationwide, and high-quality materials are delivered to the customers. In addition, those precut factories who consider adopting Apple Pin System (APS construction method) may do so by customizing existing precut machines and adding CAD or program exclusive for the System, so capital investment can be minimized.

Apple Pin

System

features

06

Workability

In Apple Pin System (APS construction method), standard procedure is to use joint for the connecting part and build by placing beams, which is similar to conventional post and beam structural system. Since bolts or nuts are not used in the foundation structure, backlash is unlikely to occur, and drawing and control of tightening torque are easy. In addition, installation is made after placing the beams, so it is safe and the sense of discomfort is abated for the workers on the construction site.